Digital Twins

what are they?

Make digital representation of a physical asset or a process

The Digital Twin resides in the cloud. It can show the current or past states of the asset/process —- and can point to the future and simulate the future state based on certain assumptions. It also connects with the asset/process history and the Digital Thread.

Optionally supports Asset Administration Shell (AAS),a standards-based model from Industrie 4.0 initiative to implement the digital twin.

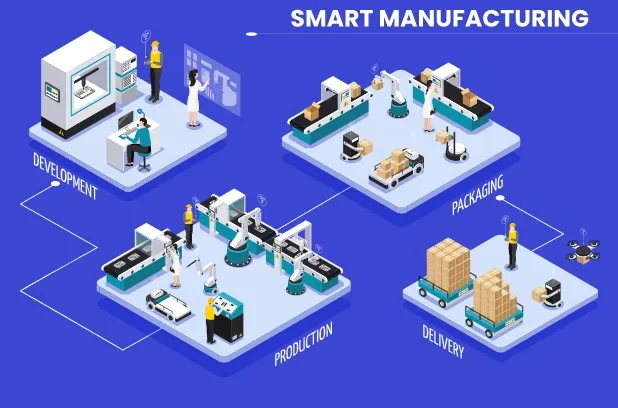

The Digital Thread begins with the design of a product and follows the product through every step of its life, from design, to manufacturing, to sale, delivery, maintenance and disposal.

It links to every system that it touches during the journey (CAD, PDM, PLM, MES, ERP, CRM, MOM, etc.) and combines the data to provide a complete “history of everything” for the asset.

The Digital Twin resides in the cloud. It can show the current or past states of the asset/process —- and can point to the future and simulate the future state based on certain assumptions. It also connects with the asset/process history and the Digital Thread.

Optionally supports Asset Administration Shell (AAS),a standards-based model from Industrie 4.0 initiative to implement the digital twin.

The Digital Thread begins with the design of a product and follows the product through every step of its life, from design, to manufacturing, to sale, delivery, maintenance and disposal.

It links to every system that it touches during the journey (CAD, PDM, PLM, MES, ERP, CRM, MOM, etc.) and combines the data to provide a complete “history of everything” for the asset.

Fleet Management

By implementing the Digital Twin of every asset in a fleet (could be windparks, could be all cars anywhere in Europe, could be all refrigerators sold anywhere) we gain tremendous advantages. We can not only tell you about every asset, but we can start to make statements about the entire fleet, and we can simulate the entire system’s behaviour into the future.

We can provide management dashboards, track metrics to optimise KPIs over time, etc.

We can provide management dashboards, track metrics to optimise KPIs over time, etc.

What we offer

We analyze the assets, agree on how to model them as a digital twin. Then we provide a cloud-based architecture and implement the back-end. In cooperation with the customer’s product team, we start to pull in the data. Then, based on their requirement, we:

- Provide Digital Twin web interface of every asset

- Provide Management Dashboards of entire Fleet

- Provide specialised views (manufacturing twin, logistics twin, maintenance twin, etc.), which are all just different manifestations of the twin.

- We help to define the digital thread and work with their IT and SIs to realise those parts of it that they regard as critical.

- We offer integration services for manufacturing, logistics and other partners to gain data needed for the full Digital Twin